You walk through one of the vast industrial plants in the world, and the air is singing with noises of machines … or rather, machines … and forklifts whisk past carrying absurdly heavy loads, and everything you see feels raw and full of intent, powerful. Now look down. What are you standing on? Chances are it’s some gritty, unspectacular diamond-patterned grating that you never even notice. Ah! There’s the unsung hero of the industrial world, the working horse that never calls in sick: expanded metal sheet 4×8 humble yet mighty- totally unbiased opinion here. This is not some wacky piece of metal but a manifestation of intelligent design. It’s like so around us that we’ve been blinded by its genius, but today we peel back the curtain. What makes this particular size and shape so ubiquitous in so many applications, from the runway underfoot to the fence that surrounds a property? Let’s get down to the nitty-gritty, fabulous world of these panels and see why the expanded metal sheet 4×8 is just the superior industrial choice, no doubt.

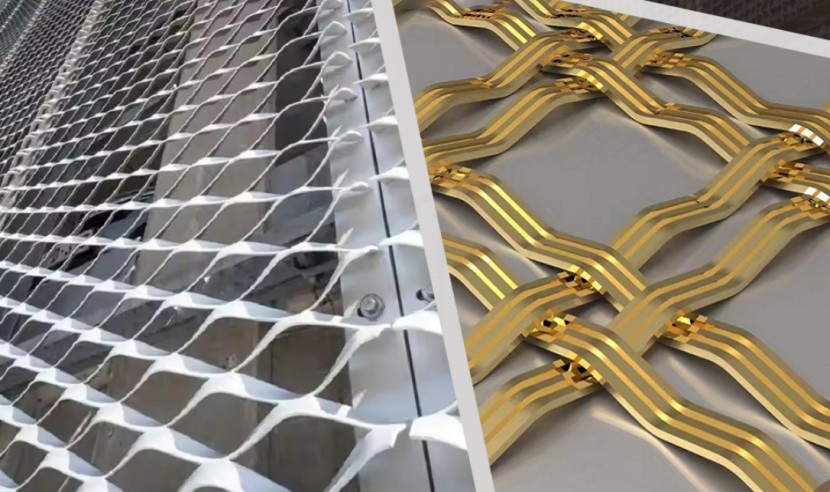

Starting with a single planar metal sheet, no weaving, no welding, no complex assembly, it is only fed to a machine which with exquisitely accurate violence slits and stretches the sheet with uncanny coherence into one beautiful net of diamonds. It’s in the expanding where the magic happens. Generally, you get a bigger sheet than what you started off with and yet there is practically no waste. The material is not cut out, it is changed. That is the first intimation of its superiority. Think about that for a moment. In a world noisy with cries for sustainability and reduction in scrap, the manufacturing process for an expanded metal sheet 4×8 is indeed an excellent lesson in efficiency. That’s more coverage from less raw material, which is a win for both the bottom line and the planet. This isn’t a product that’s been simply cobbled together, it’s a product freed from a solid block, quite literally expanded into existence.

Unlocking the Potential of a 4×8 Footprint

So here’s the magic number – 4 x 8. And not plucked out of thin air. No, this dimension is the foundation of modern North American construction and manufacturing. Walk into any lumberyard, any building supply store, and chances are pretty good that you’ll be faced with a pile of plywood sheets, drywall panels, and insulation batts-all in the 4×8 foot format. Typically, an entire skeleton for a building is thought of in this grid framework. Thus, the introduction of expanded metal sheet 4×8 directly puts that much more control into the job site’s hands- an intuitive fit. Yet, it requires no complex cutting and fitting to cover an area in standard size. He may lift a panel out of the truck, bear it (albeit with much strain depending on the gage), and dump it into place. Such compatibility saves an enormous amount of time and labor-savings that translate directly into money in the industrial world.

The easy convenience of such normal size is unimaginable. Need to build a mezzanine floor for storage? Bolt a few expanded metal sheet 4×8 panels to the supporting structure, and thyristors and you’re done. need to erect a safety guard for a mammoth piece of equipment? earn The panels are put up quickly when designing an enclosure for machines that get out of hand. It often comes out to just the right size stuff. The rules could be so cut and relaxed and overbearing for designing problems and buying solutions. It won’t force some maintenance manager by requiring a dozen custom-sized specialty items. Instead, all he has to do is reach for a stack of standard expanded metal sheet 4×8 panels in the warehouse, it happens to be a universal spare part for a thousand different problems. This logistical modesty is—at the core-an integral superiority: it is the industrial equivalent of a Swiss Army knife-a standard tool that can handle any number of design problems.

Besides, handling and material transportation for this size become very well organized. For this size, flatbed trailers, containers or rackings even racking can be prepared according to these dimensions in view of the loads they will bear. Stacking and securing a pallet of expanded metal sheet 4×8 panels are much easier, and that processing becomes simple. It just makes the whole operation more fluent whereas conventionally having to ship rather a palette of mixed sized- specifically, shaped grating would only invite sloppiness and destruction. The very benefit of expanded metal sheet 4×8 is not confined within the walls of a factory, it resonates throughout the supply channel from the manufacturer to the very end user. This is no product, this is a precisely sized tooth in the cog of the huge machine of industry.

Strength and Savings in Harmony

But let’s cut to the chase: it’s the fantastic strength-to-weight ratio. This is where the expanded metal process really excels. When that solid sheet is slit and stretched, it doesn’t just become a net, it becomes a rigid, triangulated structure. Those diamond openings aren’t empty space, they’re crucial to the strength of the panel: it’s basically an I-beam. The center web of an I-beam carries enormous compressing force with least material and the flanges bear the brunt. An expanded metal sheet 4×8 works on much the same sort of principle. The filaments are little flanges, while the nodes where they intersect are extremely sturdy because they are just one piece of metal. The upshot is that light expanded metal sheet 4×8 supports surprisingly large weight, which makes it perfect for platforms, pathways, and ramps.

Such inherent strength results in cost savings too, due to the optimization of material resources. Perhaps, made up of lesser metal to achieve an equal or even higher strength barrier compared to solid panels, its cost comes down due to lower material requirements for production. However, the cost-reducing characteristic does not stop there either. That reduced weight makes them easier to handle, lowers labor time costs, and may allow for lightly designed supporting structures. One does not have to construct such a massive steel structure just to support a floor built out of those expanded metal sheet 4×8 panels. A lighter and less costly structure often suffices for the purpose. This cumulative effect on project costs is the main thing going for it. You are not just buying a panel, you are buying something that makes every other element in the project that little bit less onerous and that little bit cheaper.

And let’s not forget about the design alternatives the expanded metal sheet 4×8 can be offered in – flat and raised. The flattened one passes an additional roller leveling process, which is why it ends up extremely smooth and flat for most flooring or grating applications. The raised one has those classic rough diamond-shaped edges, perfect for anti-slip – a requirement on greasy or slippery industrial walkways. It can be fabricated from several materials: carbon steel, Galvanised steel for corrosion resistance, stainless for highly corrosive chemicals, and even aluminum to keep it light or in non-corrosive applications. This means an appropriate expanded metal sheet 4×8 is available for almost every imaginable industrial challenge.

A Lesser-Known Champion for Safety and Visibility

In industrial safety is not considered a product but is the basic requirement. Thus, here is another application of the expanded metal sheet 4×8. The open mesh design is advantageous in that when it is used as flooring on a mezzanine or a catwalk over some machinery, it allows lighting, air circulation, and heat to pass through. This avoids the accumulation of types of dust and debris, and more importantly the flammable gases that could turn ignition sources. It scrubs off dark corner pockets of space that can accumulate hazards within an industrial setting. Such passive ventilation would indeed prove to be very beneficial towards the safety of the workmen. Moreover, even visibility through the floor is a great safety asset. A worker on an upper level can see work below him or her level, while one below can see problems above him or her level-hence much better situational awareness compared to what solid floors could ever provide.

Such open design is very important and has to do with the ease of drainage and debris management. Consider a manufacturing floor that has to be washed down frequently. A solid floor would create puddles, causing flooding. A platform constructed from expanded metal sheet 4×8 makes water, chemicals, and small debris pass through easily, keeping the working surface relatively more dry and safe. When used in outdoor applications, as sunscreens or in fencing, there is that openness that allows wind to pass through during a storm, thus reducing the load on the supporting structure compared to a solid sheet which acts like a sail. This permeability is an engineering benefit that is quite often not looked into but is crucial for end durability and safety.

The slip resistance, particularly of the raised pattern expanded metal sheet 4×8, cannot be emphasized enough. The raised strands provide myriad biting edges for shoe soles to anchor onto, even when the surface is coated in oil, grease, or water. This is an inherent safety feature that does not need any additional coatings or treatments, it is inherently safe. If you add this slip resistance to its structural integrity and the fall through protection it provides, you have a material which directly protects the people who work around it and on top of it. It’s a silent guardian, a watchful protector of the industrial workforce.

Beyond Simple Flooring: Exploring a World of Possibilities

We’ve been talking a lot about covering floors, and walkability but to limit the increased metal sheet 48 to just one role would be an enormous injustice. Its utility spills over into virtually every industry. In the architectural world, they are used for beautiful facades and sunscreens that play dynamic games with lights and shadows. They serve as security fences and gates, they form a strong barrier but do not claustrophobically give in, like a solid wall. An expanded metal sheet 48 fence is truly secure and at the same time quite open so one can see right through it while trying to keep the bad guys out.

Walk into most commercial spaces, and you might see it on decorative panels, radiator covers, or even just incorporated as an interesting design element within retail spaces. It’s that industrial-chic look that has helped make it a favorite with designers looking to add some texture and a sense of robustness to their interiors. In transportation, it is applied as floors in trucks and trailers, to offer a lightweight strength, and self-cleaning surface. In agriculture, sorting screens and animal enclosures make use of it. In filtration and screening, we on our own use specific sizes of expanded metal sheet 4×8 to, separating the aggregates and other materials. Only the middle part of the content has been used while rewriting the text.

True, the expanded metal sheet 4×8 is a chameleon. It can be as simple and rough as unsophisticated floor grating at a coal mine, and, or so fine, powder-coated screening at a luxurious apartment building. Such flexibility arguably represents the ultimate in design excellence. Pure functionality. It does not dictate a singular use but rather screams innovative application. To the fabricator, the standard expanded metal sheet 4×8 is not just a panel, it is potential for one hundred different solutions. It is this potential that cements its standing as an industrial icon.

Next time you find yourself in a warehouse or factory or maybe even a modern office building, take a second to look around you. That humble diamond-patterned grid isn’t just metal, it’s a work of efficient manufacturing, a cornerstone of structural logic, a protector of safety, and an embodiment of flexible design. It’s the silent, constant partner industry is founded on. From its cradle-to-grave waste-free birth and on to its countless second lives, the expanded metal sheet 4×8 is not merely some commodity you buy, it’s that smart, solid, and supremely capable choice you make.