In the realm of construction and manufacturing, glass handling is a critical component that demands precision and care. The way glass is managed from production through to installation can significantly impact its performance and safety. As technology continues to advance, the industry is experiencing a transformative shift in how glass is handled. This blog explores how modern technologies and tools are revolutionising handling, improving efficiency, safety, and overall quality.

The Evolution of Glass Handling Technologies

Historically, handling was a labour-intensive process, often involving manual effort and considerable risk. The introduction of modern technologies has dramatically changed this landscape. Today, automation and sophisticated machinery play pivotal roles in ensuring that glass is handled with the utmost care and precision.

One of the most significant advancements is the development of automated handling systems. These systems utilise robotic arms and conveyor belts to manage glass panes throughout the production and installation processes. This automation not only reduces the risk of human error but also enhances the speed and efficiency of handling operations. With these systems, glass can be moved, cut, and installed with a level of precision that was previously unattainable.

Advanced Tools for Enhanced Safety

Safety is a paramount concern in glass handling, given the inherent fragility of the material. Modern technologies have introduced several tools designed to minimise risks and protect both workers and the glass itself.

Vacuum lifters are a prime example of such tools. These devices use suction to securely lift and transport glass panes, significantly reducing the likelihood of breakages. The precision of vacuum lifters ensures that glass is handled gently, which is essential for maintaining its structural integrity. Additionally, these tools are often equipped with advanced sensors that detect any potential issues, further enhancing safety.

Another innovation is the development of protective coatings and films. These products are applied to glass surfaces to enhance durability and resistance to damage during handling. Such coatings help to prevent scratches and other surface imperfections that can compromise the quality of the glass.

The Role of Smart Technology in Glass Handling

Smart technology has made a considerable impact on the handling industry. The integration of sensors, data analytics, and connectivity has introduced a new level of sophistication to handling operations.

For instance, smart sensors can monitor the condition of glass throughout its journey from production to installation. These sensors provide real-time data on factors such as temperature, pressure, and vibrations. By analysing this data, it is possible to detect any anomalies that could indicate potential damage. Early detection allows for prompt intervention, reducing the risk of costly breakages and ensuring that the glass reaches its final destination in optimal condition.

Moreover, smart technology enables more efficient management of handling logistics. Advanced software systems can track and coordinate the movement of glass panes, optimising routes and scheduling to minimise delays and disruptions. This level of coordination is crucial for large-scale projects where timely delivery and installation are essential.

Innovations in Glass Installation

The advancements in handling technology extend beyond transportation to the actual installation process. Modern tools and techniques have greatly improved the efficiency and accuracy of glass installation.

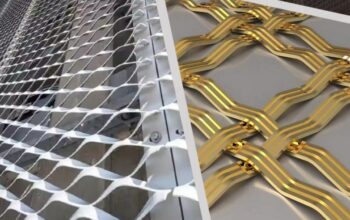

One notable innovation is the use of precision glazing systems. These systems allow for the accurate placement and alignment of glass panes during installation. By employing automated systems and precise measurements, the risk of misalignment is significantly reduced, leading to a more aesthetically pleasing and functional finished product.

Additionally, advanced mounting and fastening solutions have been developed to ensure secure installation. These solutions are designed to accommodate various types of glass and frame configurations, providing flexibility and reliability. The use of these tools ensures that glass is installed correctly and remains securely in place over time.

The Environmental Impact of Modern Glass Handling

Modern technologies in handling are also contributing to environmental sustainability. Many of the new tools and techniques are designed with energy efficiency and waste reduction in mind.

For example, automated systems and smart technology can optimise the use of resources, reducing energy consumption and material waste. By streamlining processes and minimising errors, these technologies help to lower the overall environmental footprint of handling operations.

Furthermore, the development of eco-friendly coatings and adhesives aligns with the industry’s growing emphasis on sustainability. These products are designed to be less harmful to the environment while still providing the necessary protection and performance for glass.

Conclusion

The transformation of glass handling through modern technologies and tools has brought about significant improvements in efficiency, safety, and quality. From automated systems and advanced tools to smart technology and innovative installation techniques, these advancements are reshaping the industry. By adopting these modern solutions, businesses can enhance their handling practices, ensuring that glass is managed with precision and care from production through to installation.

As the industry continues to evolve, staying abreast of these technological advancements will be crucial for maintaining a competitive edge and achieving optimal results in handling. Embracing these innovations not only improves operational efficiency but also contributes to a safer and more sustainable approach to handling glass.